Incaline®

The preferred product for the protection of concrete, masonry and steel

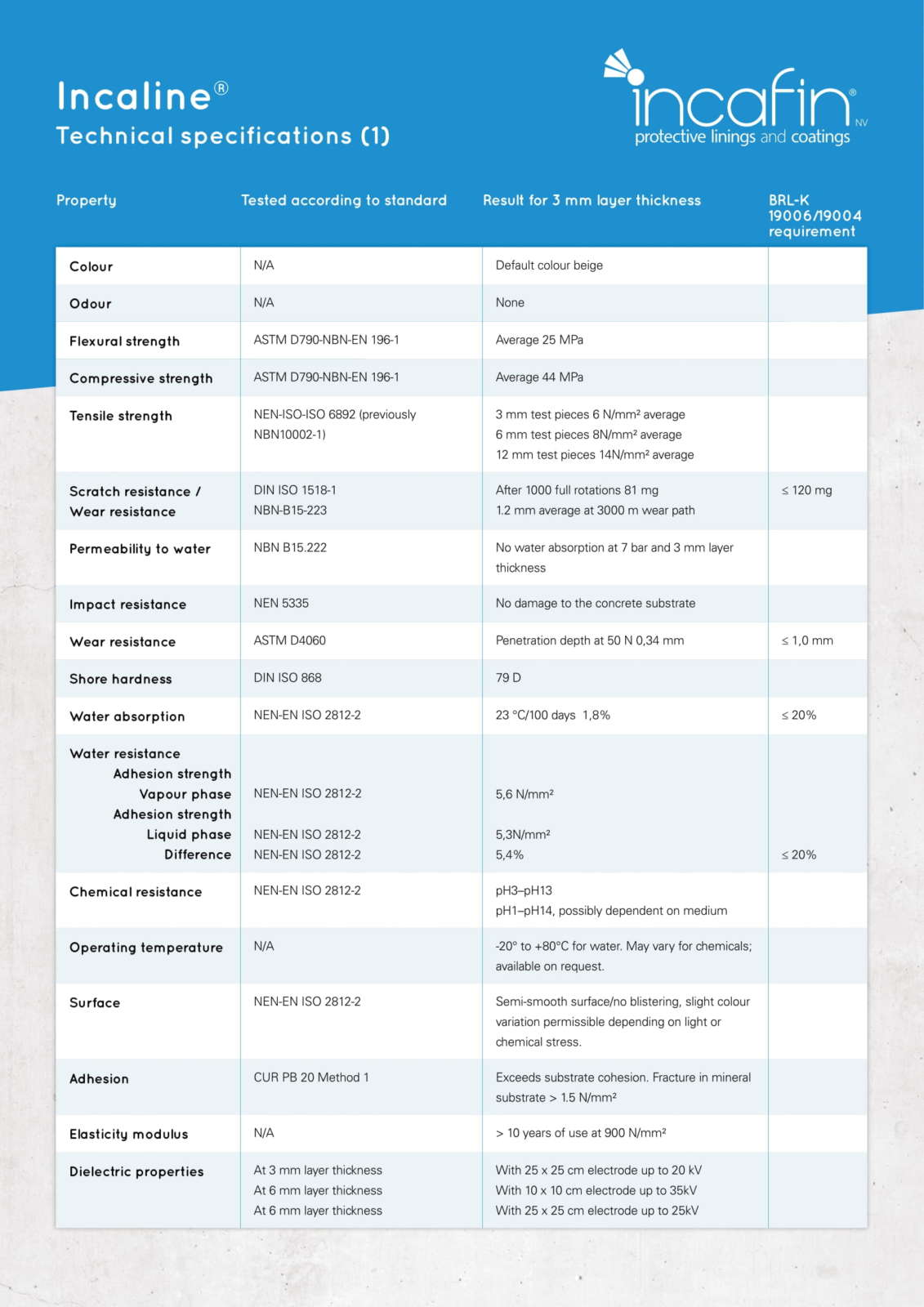

Detergents, laundry detergents and chemical products all contribute to the deterioration of our concrete and steel structures. Applying Incaline®, a solvent-free synthetic fibre-reinforced epoxy, prevents deterioration, ensuring a longer life span. This unique technology ensures the high chemical resistance of your structures and has superlative mechanical and physical properties. Click here to view the unique technical properties of Incaline

Incaline® is a solvent-free synthetic fibre-reinforced epoxy, that is applied cold – with no risk of blistering as a result of vapour pressure – with a minimum layer thickness of 3 mm.

It can be applied to dry as well as 100% water-saturated surfaces at a relative humidity of > 95% (which is always the case in sewers) without detriment to the coating’s quality and durability.

Incaline® is guaranteed to be waterproof and gas-proof meaning neither gases (H2S – vapours) nor liquids can penetrate the underlying substrate, ensuring the concrete is not affected.

Because of its high chemical resistance, the product is applied as corrosion protection both for domestic and industrial wastewater. The KIWA product certification for wastewater applications, the only one of its kind in this industry, is your guarantee of quality and durability. The BRL K 19004, an application certification, offers an additional guarantee after the application of Incaline®. Incaline® is not affected by osmosis, unlike many other fibre-reinforced systems.

The excellent dielectric properties are directly related to the coating’s chemical resistance and are used to measure the coating’s chemical resistance.

Want to learn about possible applications? Read more here >

Incaline® does not shrink.

Properties as a result of the presence of synthetic fibre and its technical properties:

- Excellent adhesion to the substrate because Incaline® does not shrink due to the absence of solvents.

- Excellent structural properties – physical and mechanical properties (E-modulus, flexural strength, three point bend test – high impact resistance);

- Increased resistance against plastic deformation;

- Lasting increased elasticity modulus;

- Increased resistance against creep;

- Adhesion strength on concrete is greater than the tensile strength of the concrete. A chemically contaminated mineral substrate does not negatively impact the adhesion properties of the applied coating, ensuring it can also be used on old structures (renovation);

- Excellent resistance against crystallisation pressure in salt-loaded substrates;

- No water absorption, ensuring lasting adhesion in the long term (i.e., durability). This is not the case for cement-based coatings.

- Greater resistance against ageing – in case of degradation over time (typical of polymers) the fibre matrix guarantees the physical and mechanical properties;

- Lasting tear-bridging properties preventing water infiltration (compensates for concrete settlement);

- Excellent expansion and shrinkage capacity (fatigue resistance) without cracks;

- Reduction of internal stress in the coating, guaranteeing a longer life span;

- Higher resistance against water pressure from the outside. Can independently absorb water pressure up to 5 bar;

- Can withstand vibrations, car and HGV traffic.

- No internal stress after curing;

- No problems with vapour pressure (blistering) because of the difference in temperature with the substrate;

- Lasting permanent adhesion to the substrate, including on salt-loaded substrates;

(Hexavalent) chromium compounds are carcinogenic and harmful to humans and the environment. Incaline® does not contain any (hexavalent) chromium compounds. As such it complies with Directive 2004/37 of the European Parliament and Council.

Heavy metals are considered toxic and harmful to humans and the environment. Heavy metals can leach into the soil and can thoroughly contaminate our water table. Nor does Incaline® contain any heavy metals. This was tested in solid material using ICP-OES (analysis with plasma and a spectrometer) after microwave-assisted acid digestion.

An accredited independent laboratory recently tested Incaline® for the presence of volatile organic compounds (VOC) in the product. These chemicals are hazardous for the environment and human health. The results were astounding: The measured value was 0.004%, which is extraordinarily low.

Incaline® more than complies with the European Union’s directives and may rightfully be considered an environmentally friendly, ecological protective solution for concrete, steel and masonry!

Want more information? Contact us to request the full report.

Incaline® was formulated to fulfil the output requirements of environmental standards in terms of the ‘Best Available Techniques’ (BAT). These are the most effective methods, that are both technically and economically feasible, to prevent emissions and other negative environmental impacts.

The formulation of Incaline® always takes ecology and environmental aspects into account. When better raw material alternatives are available, the formulation is optimised and adapted, whenever more environment-friendly raw materials can be used both from an economic or technical viewpoint. The starting premise, however, is to always maintain the product’s high quality and sustainability.

No solvent is released during the processing (solvent-free epoxy), preventing the release of noxious vapours into the environment.

Nor is there any leaching of harmful substances after curing, which may contaminate the soil and surface water in the long term. Leaching tests were performed to this end.

Incaline® can thus be considered an ecological, environment-friendly product. The application of Incaline® reduces the carbon footprint of structures, because their life span is extended to 75 years.

At the end of its life span, Incaline® can be ground up and processed as residual waste. This means it can be used as a substrate for foundations, contributing to the circular economy.

After application as a waterproof coating, a certificate of impermeability can be issued by an independent laboratory with a 10-year warranty, covered by an external insurer.

The above properties are backed up by test data, which are available upon request.

Sealcoat

| Flexural modulus | 3,6 GPa |

| Adhesion | Min. 1.5 N/mm² (concrete fracture) |

| Impact resistance | > 13 KJ/m² |

| Chemical resistance | No changes (pH 3) No changes (pH 13) |

| Temperature resistance | -40°C tot +150°C |

| Barcol hardness | > 40 |

| Stretch at breaking point | > 4% |

| Density | approx. 1.7 g/dm³ |

The formulation of Sealcoat® is based on the latest, new and best available technology (BAT). When applied as a coating, Sealcoat® offers cathodic protection from corrosion, acting as corrosion protection for steel in addition to offering protection from concrete corrosion (as a concrete coating or lining). This system is ideally suited for protecting industrial concrete floors, whether from reinforced concrete or not, and drip trays.

Sealcoat® offers high chemical resistance against organic and inorganic acids, alkaline products and salts, and several solvents.

Incafin NV’s range includes the ‘Sealcoat® concrete primer’, the ‘Sealcoat® metal primer’, ‘Sealcoat® VE’ (formulated vinyl ester resin) and the ‘Sealcoat® Topcoat’.

Sealcoat® is non-permeable. The vapour density of Sealcoat® is up to three times greater compared with polyester resin formulated systems. Nor is there any risk of hydrolysis when using Sealcoat® unlike with polyester resin.

Sealcoat® offers good impact resistance and is able to withstand mechanical compaction while maintaining its original properties.

The consistent level of quality which Incafin NV applies for the formulation of its products, with in-house controls of each production batch, offers optimum quality assurance. Incafin NV also dispenses technical advice after consulting with customers. The close collaboration with these customers – ensuring they are given the right advice – contributes to a durable result.

The short application time, combined with the rapid curing, is definitely an asset, ensuring that structures can be protected within a short time frame. After just one hour of curing the system can be used, except in case of immediate high chemical and/or mechanical compaction. The curing continues during the first days after application, until complete reticulation of the system is achieved. After this stage, chemical agents can be used on Sealcoat®.

After application, a ‘certificate of conformity of coating’ can be issued for a five-year period.